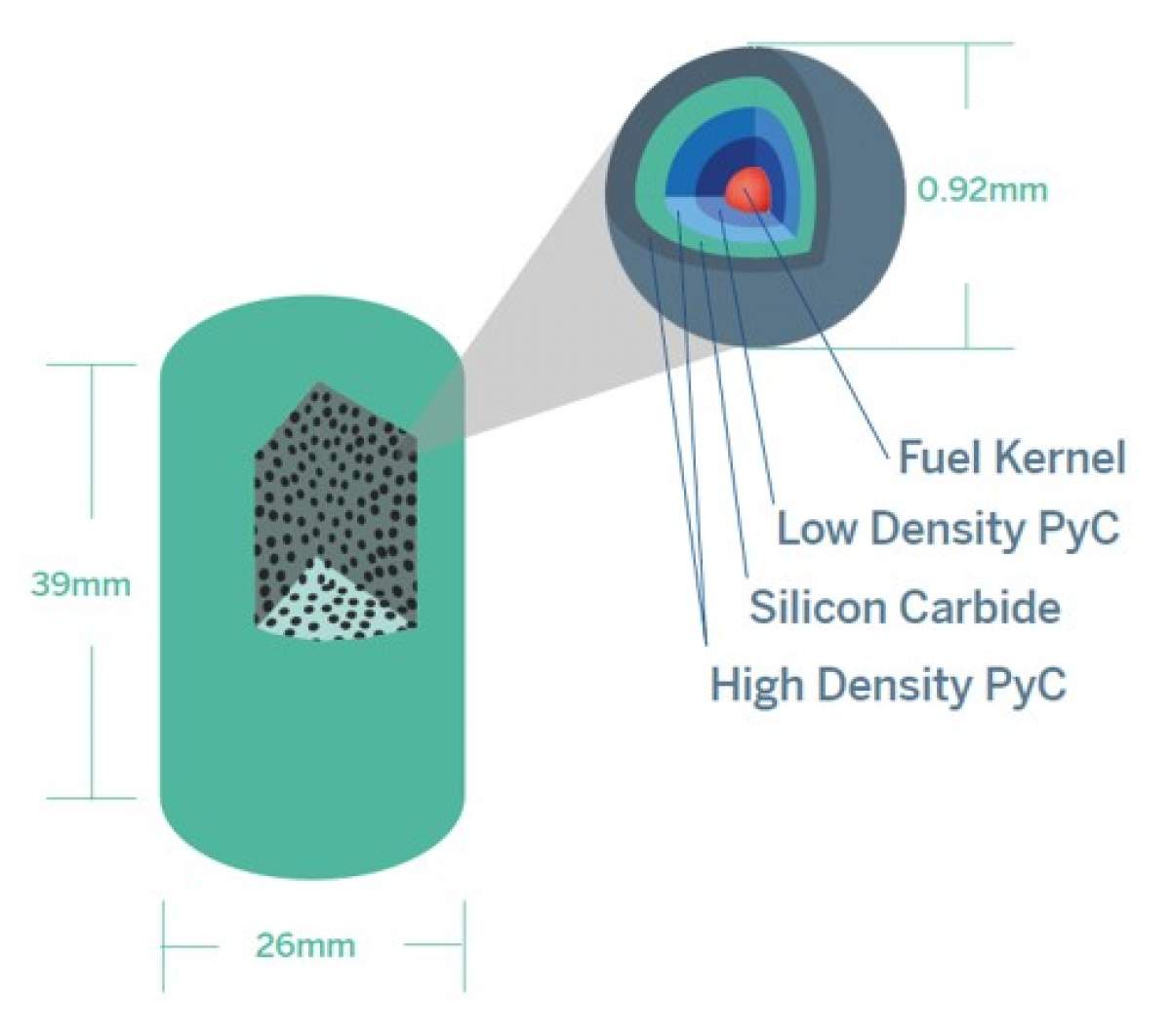

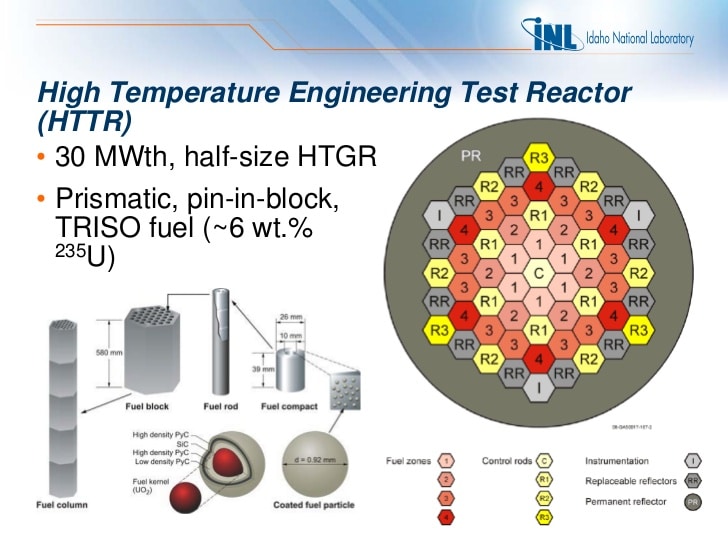

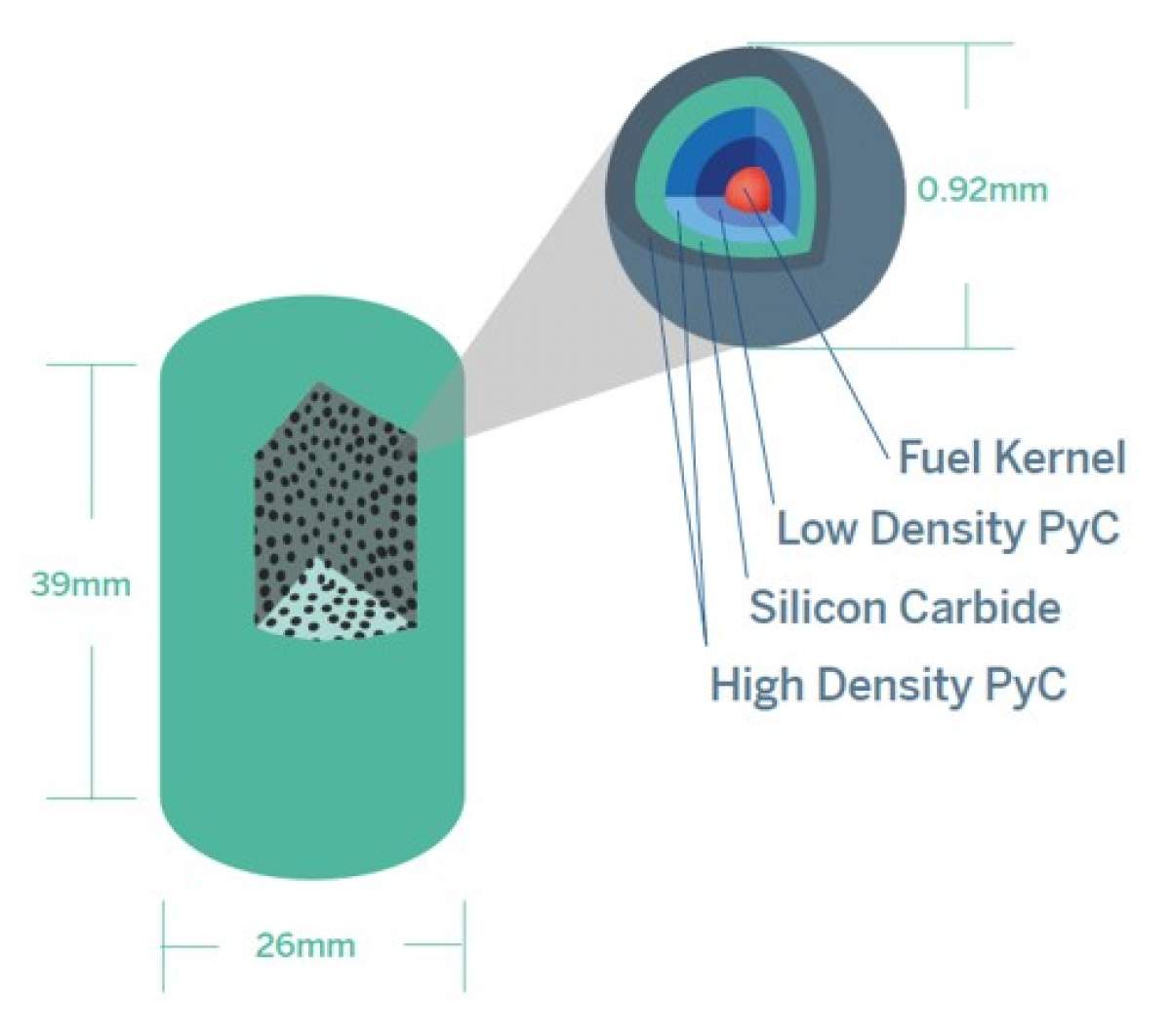

U-Battery has always been a commercially-focussed market-led development intended to compete with other non-nuclear options. Since the main ideas behind the U-Battery are inherent safety modularity and near-term utilization the U-Battery has been developed based on currently mature High Temperature Reactor HTR fuel blocks utilizing standard TRISO particles as fuel.

Design And Technology U Battery

U-Battery 479 followers on LinkedIn.

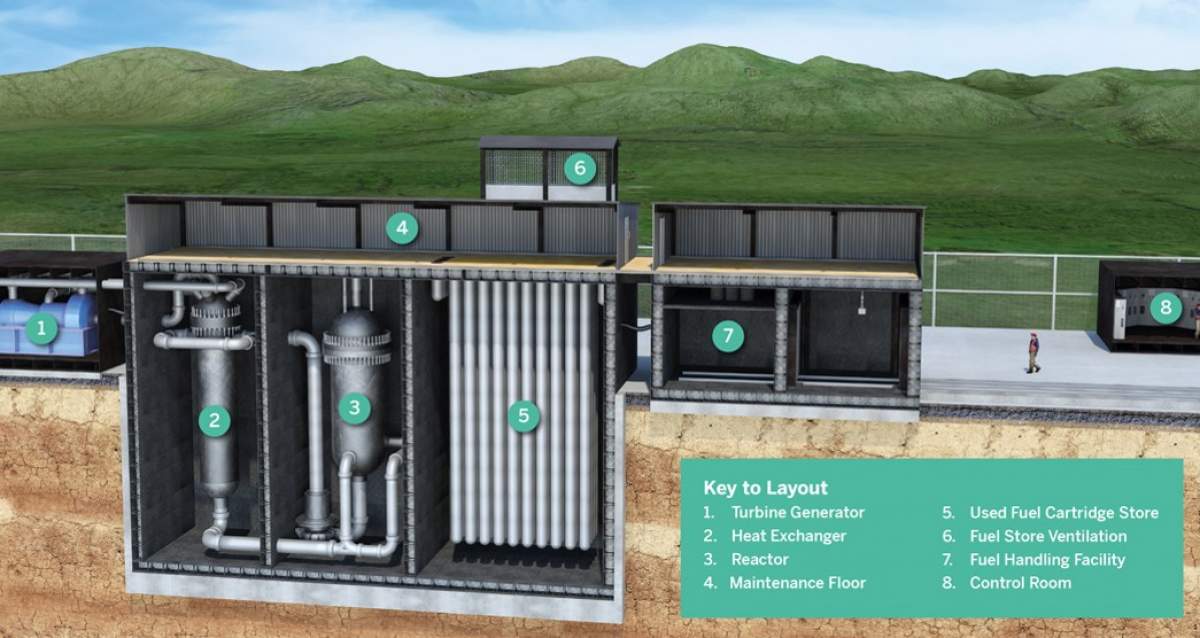

. Inherently safe Self regulating minimal control and maintenance Natural Circulation Cooling High reliability and availability Burnup of at least 10 FIMA. 10 MWth gas cooled graphite moderate reactor. This full-scale model shows how the reactor can be constructed using modular techniques.

Concept design and initial sizing. Each unit is projected to cost about GBP50 million USD68 million. U-battery is an advanced small modular reactor based on proven high-temperature gas cooled reactor technology using highly accident tolerant TRISO fuel and delivering a scalable output from 10 MW thermal 4 MW electrical with a footprint of 350 square metres.

This report discusses the four primary methods for power upgrading. It is being developed by a consortium of Amec Foster Wheeler Cammell-Laird Laing ORourke and Urenco. U-Battery has always been a commercially focussed market led development able to compete with other non-nuclear options.

Last month Cavendish Nuclear and U-Battery unveiled a full-scale model of U-Batterys advanced modular reactor. The feasibility of upgrading the power of the Heat Pipe Space Nuclear Reactor HPSNR system design was investigated. Economic Analysis of the U-Battery.

In July 2020 it was one of three vendors to progress from Phase 1 to Phase 2 of the competition and was awarded 10m of funding to initiate design and development work. It is the fourth reactor design to do so. An exception is U-Battery a micro-modular reactor design distinct from larger SMRs promoted by a company formed by a consortium of nuclear and other engineering firms including Amec Cammell Laird Laing ORourke and URENCO.

Reactor Structural and Fuel Design C. U-Battery design The conceptual design was developed by the Universities of Manchester UK and Delft Netherlands after the project was initiated by Urenco a. November 2 2021.

The conceptual design was developed by the Universities of Manchester UK and Delft Netherlands. Design is based on known process components and principles previously demonstrated in prototype reactors such as DRAGON at Harwell from the 1960s. The U-Battery reactor is under development by a consortium that includes Urenco Kinectrics which is leading the design review and licensing and Jacobs a global project management company.

The concept design of U-Battery was developed by the Universities of Manchester the Dalton Institute UK and the Technology University of Delft Netherlands after the project was initiated in 2008 by Urenco. The Urenco-led U-Battery consortium has completed the first stage of Canadian Nuclear Laboratories CNL invitation to site a first-of-a-kind small modular reactor SMR at the Chalk River site. Corroborating figures from scaling tools.

Richard is a Chief Technologist within the Jacobs Advanced Reactor Group and a key member of the U-Battery project team responsible for developing the design of the reactor power plant to date and the consequent research and development programmes for the. The U-Battery design is driven by the principle of simplicity which enables a shorter timeframe and a low cost low risk design and licensing process. The conceptual design was developed by the Universities of Manchester UK and Delft Netherlands after the project was initiated by Urenco a global leader in the nuclear industry.

About the design U-Battery is an advancedsmall modular reactor capable of providing a low-carbon cost effective locally embedded and reliable source of power and heat for energy intensive industry and remote locations. U-Battery received additional funding from BEIS to design and build mock-ups of the two main vessels for the reactor and the connecting duct. Helium gas is the primary coolant.

It has the potential to drive significant economic benefits through commercialisation and deployment in global markets. Nitrogen gas is used as the working fluid for a closed Brayton cycle power conversion unit. Cost Figure provided by Cammell Laird.

Primary Gas Circulator 1 300000000 300000000 Howden expression of interest letter 252 Moderate Quote from Howdens based upon specifications determined using U-Battery Thermodynamic Cycle tool. We are dedicated to pairing technological innovation with nuclear energy development and contributing towards the fight. It is moved with an electrically powered circulator through reactor and through a helium to nitrogen heat exchanger.

U-Battery is developing a micro nuclear reactor a category of nuclear power reactors that produce less than 10 MWe that uses a helium cooled high temperature reactor with hexagonal prismatic fuel elements similar to the ones used for the Ft. An AdvancedSmall Modular Reactor providing low cost low risk low carbon off-grid energy with a high heat output U-Battery is reimagining the way we power peoples lives through sustainable energy development. Core Design of the U-Battery B.

Increasing the thermal power output to the reactor core pulse-mode operation improving the heat rejection and improving the thermal-to-electric energy. 5 Executive Summary 1. U-Battery has also received additional funding from the Department for Business Energy and Industrial Strategy BEIS to design and build mock-ups of the two main vessels for the reactor and the.

U-Battery Plant Layout and Operation D. The particular configuration and assembly of components in U-Battery is a novel deployment. Introduction In the past fifty years the size of nuclear reactors has.

The investment was awarded under the Call for Advanced Manufacturing and Materials Phase 2B. The event was held at the Whetstone facility which is located in Leicestershire and owned by Cavendish Nuclear. In addition to the Advanced Manufacturing and Materials programme U-Battery is participating in Phase 2 of the UK Governments Advanced Modular Reactor Competition.

The U-Battery is a very small reactor 20 MWt for process heat applications with the following features.

U Battery Micronuclear Power With Intriguing Business Model Atomic Insights

4 Megawatt Modular Micro Nuclear Reactor Is In Canadian Pre License Review And Targets 2025 For Demo Reactor Nextbigfuture Com

Uk S U Battery Awarded A A 10m To Deliver Innovative Nuclear Technology

U Battery Full Scale Vessel Mock Up Demonstrates Efficiencies Of Advanced Nuclear Technology News U Battery

Design And Technology U Battery

Tracking The Latest Developments In Small Modular Reactor Technology

4 Megawatt Modular Micro Nuclear Reactor Is In Canadian Pre License Review And Targets 2025 For Demo Reactor Nextbigfuture Com

0 comments

Post a Comment